Refrigeration and Air Conditioning Fundamentals

This comprehensive guide explores the foundational principles of refrigeration and air conditioning technology‚ encompassing thermodynamic cycles‚ refrigerant types and their environmental impact‚ and the basic operational aspects of various systems. It delves into essential concepts for understanding and applying this crucial technology.

Thermodynamic Cycles in Refrigeration and Air Conditioning

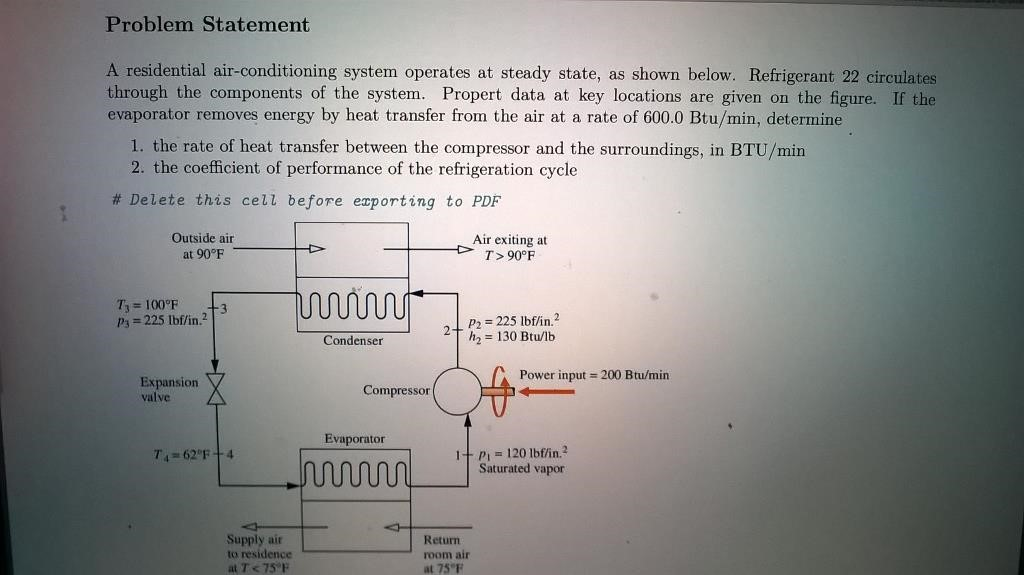

Understanding thermodynamic cycles is fundamental to refrigeration and air conditioning. The vapor-compression cycle‚ a dominant method‚ involves four key stages⁚ evaporation‚ compression‚ condensation‚ and expansion. Refrigerant absorbs heat during evaporation in the evaporator‚ becoming a low-pressure vapor. A compressor raises the pressure and temperature of the vapor. High-pressure refrigerant releases heat in the condenser‚ transitioning to a liquid. Finally‚ an expansion valve lowers the pressure‚ initiating the cycle anew. Absorption refrigeration systems‚ an alternative‚ utilize a refrigerant-absorbent solution‚ typically water and lithium bromide‚ eliminating the need for a compressor. Heat drives the process‚ making it suitable for applications leveraging waste heat. Variations exist‚ adapting to specific needs and energy sources‚ highlighting the diversity within these crucial cycles. Efficient cycle design is key to optimizing energy consumption and environmental impact. Detailed analysis of these cycles helps in understanding system performance and design improvements.

Refrigerants⁚ Types‚ Properties‚ and Environmental Impact

The selection of refrigerants is critical in refrigeration and air conditioning systems‚ balancing performance with environmental considerations. Historically‚ chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs) were widely used‚ but their ozone-depleting potential led to international regulations phasing them out. Hydrofluorocarbons (HFCs) emerged as replacements‚ offering lower ozone depletion but possessing high global warming potentials (GWPs). Natural refrigerants‚ including ammonia (NH3)‚ carbon dioxide (CO2)‚ propane (R-290)‚ and isobutane (R-600a)‚ are gaining traction due to their low or negligible GWPs and ozone depletion potentials. Each refrigerant exhibits unique properties influencing its suitability for specific applications. Factors like boiling point‚ critical temperature‚ and toxicity must be considered alongside environmental impact. The ongoing search for environmentally benign refrigerants with high energy efficiency drives research and development in this crucial area‚ seeking a balance between performance and sustainability. Careful consideration of refrigerant properties and environmental impact is crucial for responsible system design and operation.

System Components and Operation

This section details the key components—compressors‚ condensers‚ expansion valves‚ and evaporators—and their interplay in refrigeration and air conditioning systems. Understanding their functions is crucial for effective system operation and maintenance.

Vapor Compression Refrigeration Systems

Vapor-compression refrigeration systems are widely used in various applications‚ from domestic refrigerators to large-scale industrial chillers. These systems utilize a refrigerant that undergoes a thermodynamic cycle involving four key components⁚ a compressor‚ a condenser‚ an expansion valve‚ and an evaporator. The compressor raises the pressure and temperature of the refrigerant vapor‚ which then releases heat in the condenser‚ typically cooling to a liquid state. The high-pressure liquid refrigerant then flows through the expansion valve‚ experiencing a significant pressure drop and subsequent temperature reduction. This low-temperature‚ low-pressure refrigerant then absorbs heat in the evaporator‚ causing it to evaporate and return to the compressor‚ completing the cycle. Efficiency and performance are significantly influenced by factors such as refrigerant selection‚ compressor design‚ and system insulation. Understanding the principles governing this cycle is essential for troubleshooting and maintaining these systems effectively.

Vapor Absorption Refrigeration Systems

Unlike vapor-compression systems relying on mechanical compressors‚ vapor absorption refrigeration systems utilize heat as the primary energy source to drive the refrigeration cycle; These systems employ a refrigerant and an absorbent‚ usually water and lithium bromide‚ respectively. The absorbent solution absorbs the refrigerant vapor‚ concentrating the solution. This concentrated solution is then heated‚ releasing the refrigerant vapor. The vapor is then condensed‚ and the liquid refrigerant subsequently passes through an expansion valve before evaporating in the evaporator‚ absorbing heat from the space to be cooled. The refrigerant vapor is then re-absorbed by the weak absorbent solution‚ completing the cycle. Vapor absorption systems are often favored in applications where waste heat is readily available‚ making them energy-efficient alternatives in certain contexts. However‚ they generally have lower efficiency compared to vapor-compression systems when using primary energy sources.

Air Conditioning Systems

This section details residential and commercial air conditioning units‚ encompassing design‚ installation‚ and the principles of maintaining comfortable indoor environments. Key aspects of HVAC system design are also explored.

Residential and Commercial Air Conditioning Units

Residential air conditioning units‚ commonly split systems‚ comprise an outdoor condenser unit and an indoor evaporator unit connected by refrigerant lines. These systems vary in capacity (BTU/hr) and features‚ including smart thermostats and energy-efficient designs. Commercial units‚ often larger and more complex‚ may include packaged rooftop units (RTUs) for independent climate control in various zones of a building or centralized chiller systems distributing chilled water to fan coil units throughout a large facility. These systems often incorporate advanced features like variable refrigerant flow (VRF) technology to optimize energy efficiency and precise temperature control in different areas. Selection of appropriate units depends on factors like building size‚ occupancy‚ climate‚ and desired comfort levels. Proper installation and maintenance are crucial for optimal performance and longevity‚ minimizing energy consumption and maximizing comfort.

HVAC System Design and Installation

Designing an effective HVAC system necessitates careful consideration of several key factors. Load calculations‚ determining the heating and cooling requirements of a space‚ are paramount. This involves analyzing factors such as building size‚ insulation levels‚ window area‚ occupancy‚ and climate. Based on these calculations‚ appropriate equipment sizing is crucial to ensure adequate capacity without overspending. Ductwork design‚ for air distribution‚ is critical for even temperature distribution and minimizing pressure drops. Proper insulation and sealing are essential to prevent energy loss and improve efficiency. Installation requires adherence to building codes and safety standards. Careful consideration must be given to refrigerant line sizing and placement‚ electrical connections‚ and proper drainage. Thorough testing and commissioning are vital to ensure the system functions correctly and meets design specifications before handover to the end-user;

Maintenance and Troubleshooting

Regular maintenance‚ including filter changes and refrigerant checks‚ prevents costly repairs and ensures optimal system performance. Troubleshooting common issues‚ such as leaks or malfunctions‚ is vital for extending lifespan and efficiency.

Common Refrigeration and Air Conditioning Problems

Identifying and resolving common refrigeration and air conditioning issues is crucial for maintaining optimal system performance and preventing costly repairs. Among the frequently encountered problems are refrigerant leaks‚ which lead to reduced cooling capacity and potential environmental damage. Identifying the source of the leak and properly repairing it is essential. Compressor failures are another significant concern‚ often resulting in complete system shutdown. Regular maintenance and prompt attention to unusual noises or vibrations can help prevent premature compressor failure. Furthermore‚ issues with condenser coils‚ such as dirt buildup‚ restrict airflow and reduce cooling efficiency‚ necessitating regular cleaning. Similarly‚ clogged evaporator coils can impede heat transfer‚ impacting the system’s cooling performance. Improperly sized equipment relative to the space it’s designed to cool or heat is a common installation flaw. Finally‚ electrical problems‚ encompassing faulty wiring‚ blown fuses‚ or malfunctioning control boards‚ can disrupt the system’s operation. Addressing these issues promptly through regular inspections and timely maintenance ensures smooth system function.

Tools and Techniques for System Maintenance

Effective maintenance of refrigeration and air conditioning systems requires specialized tools and techniques. Essential tools include manifold gauges for measuring refrigerant pressure and temperature‚ crucial for diagnosing leaks and assessing system performance. Refrigerant recovery and charging equipment is necessary for environmentally responsible handling of refrigerants. Vacuum pumps create a vacuum within the system‚ removing air and moisture before charging with refrigerant‚ preventing damage and improving efficiency. Leak detection equipment‚ such as electronic leak detectors or halide torches‚ aids in pinpointing refrigerant leaks for timely repair. For electrical diagnostics‚ multimeters are essential for checking voltage‚ current‚ and continuity‚ identifying faulty components or wiring. Specialized wrenches and tools are needed for accessing and servicing various system components‚ ensuring safe and efficient work. Furthermore‚ proper safety procedures‚ including wearing personal protective equipment (PPE) such as safety glasses and gloves‚ are paramount to prevent accidents and injuries. Thorough cleaning of coils and other components using appropriate brushes and cleaning agents is essential for maintaining efficiency. Regular maintenance using these tools and techniques significantly extends system lifespan and optimizes performance.

Advanced Topics in Refrigeration and Air Conditioning Technology

This section explores cutting-edge advancements‚ including sustainable and energy-efficient systems‚ innovative refrigerant technologies‚ and smart control systems for optimized performance and reduced environmental impact.

Sustainable and Energy-Efficient Systems

The increasing focus on environmental sustainability has driven significant innovation in refrigeration and air conditioning. This section delves into the development and implementation of eco-friendly refrigerants with minimal ozone depletion potential (ODP) and global warming potential (GWP). We examine advanced system designs that optimize energy efficiency‚ such as heat recovery systems that utilize waste heat for other purposes‚ thereby reducing overall energy consumption. Discussions on variable-speed compressors and intelligent control systems that adapt to real-time needs to minimize energy waste are also included. Furthermore‚ the integration of renewable energy sources‚ like solar power‚ to power refrigeration and air conditioning systems is explored as a pathway to decarbonizing the sector. The economic benefits of adopting these sustainable technologies‚ including reduced operational costs and potential government incentives‚ are also analyzed. Finally‚ the role of building design and insulation in enhancing the efficiency of HVAC systems and reducing the environmental footprint is addressed. This section provides a comprehensive overview of the latest advancements towards creating a more sustainable and energy-efficient future in refrigeration and air conditioning;